parts needed

-d16 block, I used a y8 because it was free and still 75mm thanks brett bracket

-d17 crank,rods, pistons the dx/lx pistons give a taaaaad more CR $75 bucks off CL

$75 bucks off CL

-Rings for a d17 I went NPR

-D16 main bearings I reused the d17 rod bearings $65 for both on ebay

deck the block .030 you can go more but I have pics of what .030 looks like $50

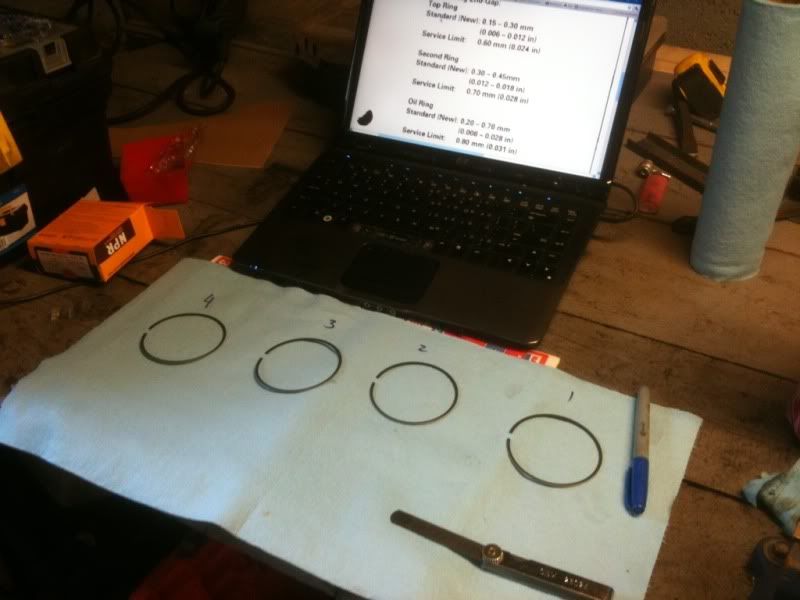

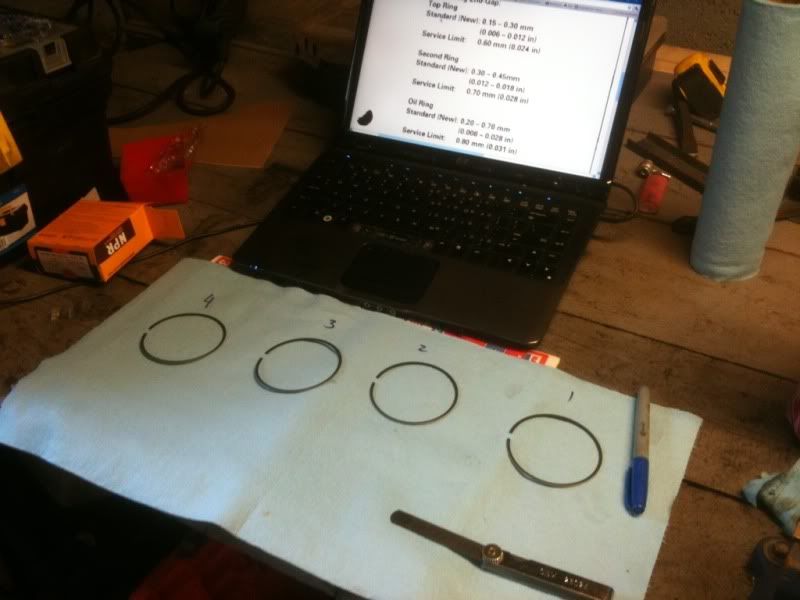

keep your #!#!#!#! organised shop towel and marker do wonders

gap your rings accordingly If you are staying NA (PUSSY) go with stock specs per helms manual, since mine will be boosted eventually I went a little loose at .014 top and .016 bottom

clock the rings accordingly (use endyne ring clocking pic) and throw those bastards in

since I reused everything I kept it organised and cleaned it with carb cleaner

put the bearings in with lube on bottom and on top

crank goes it fallowed by plastigauge then the main gurdle. Oil up the bolts tq all of them to 18ftlbs then to 38ftlbs (I hope the sequence is obvious work from middle outward) remove it and check clearances.

I lucked out and with std bearings (king) they all landed at .0015 but anything below .002 is OK if you are touchy about your clearances go with honda OEM bearings all STD, measure with plastigauge, then using the different color bearings dial in the clearance you want

but anything below .002 is OK if you are touchy about your clearances go with honda OEM bearings all STD, measure with plastigauge, then using the different color bearings dial in the clearance you want

Hope you notched that gurdle! its TIGHT not sure if its needed on all blocks I also always clean up any casting flash to help the oil return to the pan

all done

for life d16 stroker will be killing stock GSR swaps all day long!

Ill post up the oil pump, rear seal, and crank pulley setup in a bit!

-d16 block, I used a y8 because it was free and still 75mm thanks brett bracket

-d17 crank,rods, pistons the dx/lx pistons give a taaaaad more CR

$75 bucks off CL

$75 bucks off CL-Rings for a d17 I went NPR

-D16 main bearings I reused the d17 rod bearings $65 for both on ebay

deck the block .030 you can go more but I have pics of what .030 looks like $50

keep your #!#!#!#! organised shop towel and marker do wonders

gap your rings accordingly If you are staying NA (PUSSY) go with stock specs per helms manual, since mine will be boosted eventually I went a little loose at .014 top and .016 bottom

clock the rings accordingly (use endyne ring clocking pic) and throw those bastards in

since I reused everything I kept it organised and cleaned it with carb cleaner

put the bearings in with lube on bottom and on top

crank goes it fallowed by plastigauge then the main gurdle. Oil up the bolts tq all of them to 18ftlbs then to 38ftlbs (I hope the sequence is obvious work from middle outward) remove it and check clearances.

I lucked out and with std bearings (king) they all landed at .0015

but anything below .002 is OK if you are touchy about your clearances go with honda OEM bearings all STD, measure with plastigauge, then using the different color bearings dial in the clearance you want

but anything below .002 is OK if you are touchy about your clearances go with honda OEM bearings all STD, measure with plastigauge, then using the different color bearings dial in the clearance you wantHope you notched that gurdle! its TIGHT not sure if its needed on all blocks I also always clean up any casting flash to help the oil return to the pan

all done

for life d16 stroker will be killing stock GSR swaps all day long!

Ill post up the oil pump, rear seal, and crank pulley setup in a bit!

its less then desirable but I just wont rev it to the moon and it will be ok im thinking 7200 or so it will stop making power so no point in going higher

its less then desirable but I just wont rev it to the moon and it will be ok im thinking 7200 or so it will stop making power so no point in going higher

Comment